At Global Industries, we have the equipment to measure and control the most common products and materials. You can learn more about our quality inspection options by clicking the links below.

Sampling

Sampling can identify problems with the product before the product is shipped to the customer. Therefore, the sampling testing process is vital to quality control and assurance. Typically, random sampling involves selecting items randomly from a population of products for testing, according to ISO 2859.

Global Industries performs random sampling of products, and results are filed and stored in our QMS system according to ISO9001:2015.

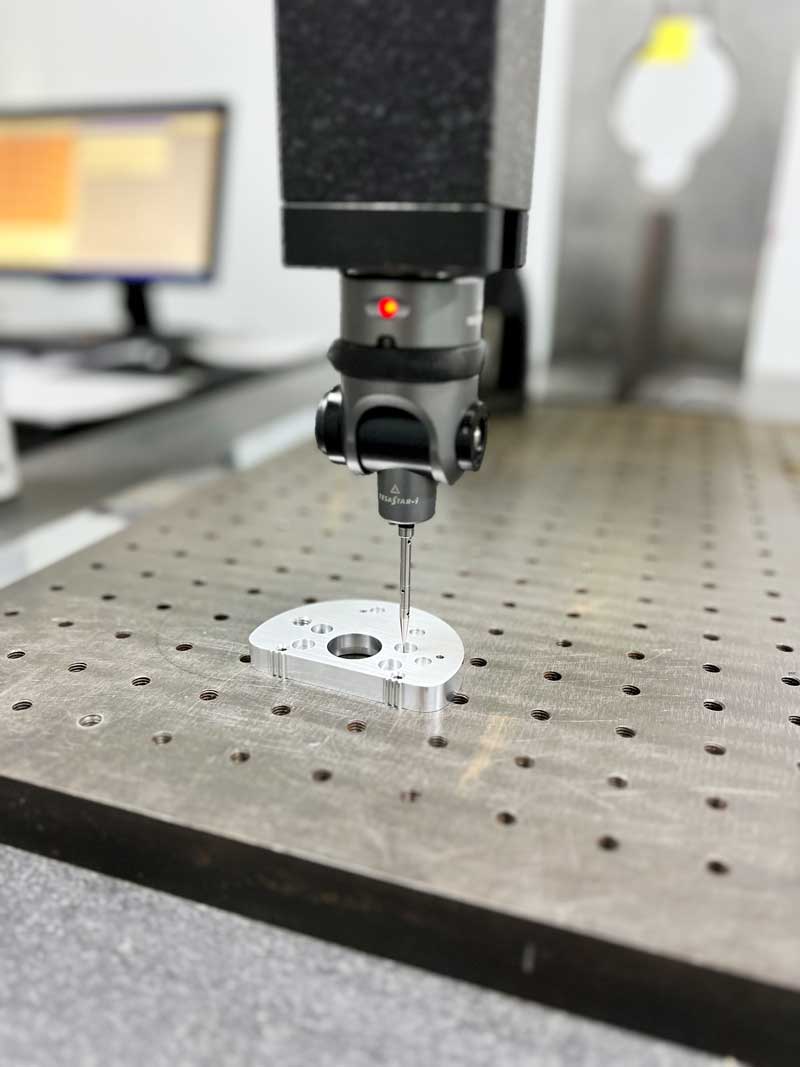

Coordinate Measuring Machine (CMM)

Coordinate measuring machines (CMM) measure geometry by sensing discrete points on objects. The CMM then calculates the probe’s position relative to the reference point and outputs the measurements to the computer for analysis and storage.

Global Industries measures complicated products on our CMM machine to identify critical dimensions and to ensure that the product meets specifications.

Material analyses

Material analysis is one of the critical focuses of Global Industries. With the Sparks Spectrometer, we can perform reliable tests. Detailed test results are provided on the composition of steel, stainless steel, and aluminium.

Customized testing

Besides dimension measuring, Global Industries also performs other tests and measurements. In this case, leakage testing is conducted on pipes manufactured according to customer specifications and design. The testing pressure is 0.5Mpa. Once the pipes have been sealed in the open ends, they are submerged in water after applying the pressure.