Global Industries

– you are in good hands

Global Industries A/S is a company registered in Aarhus, Denmark. Our head office and technology centre are located in Suzhou, China.

Global Industries is your go-to for outsourcing production in China. We specialize in industrial products made according to your design and specification. Our services include procurement process, quality control, and logistic services. We deliver the complete package where risks are minimized and deliver to your address.

Let us take care of your production needs today!

Product Solution by Global Industries

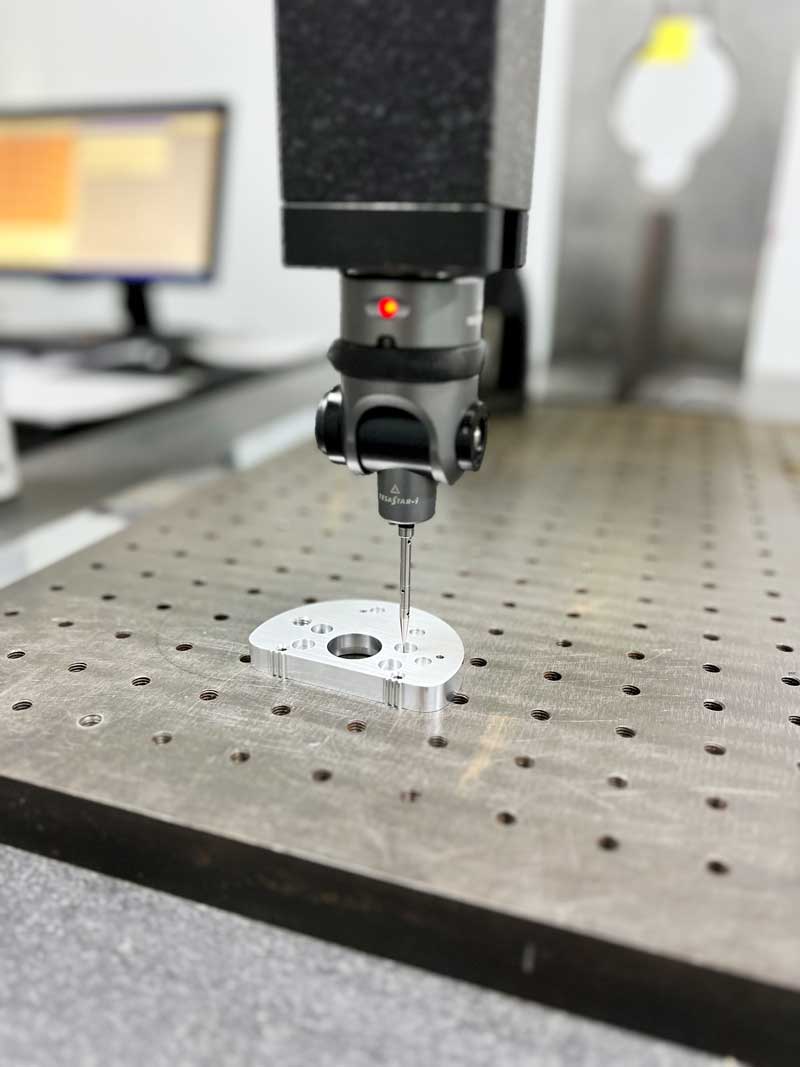

Quality Assurance

Quality Inspection

In product development, design for manufacturing is vital. Our team helps design products that consider suppliers’ manufacturing processes and capabilities. We can improve efficiency, minimize waste, and reduce costs by identifying potential issues in the design phase.

Our team works closely with clients throughout product development, providing guidance and advice at every stage. Design for manufacturing expertise enables us to bring ideas to reality quickly and efficiently.